|

RANK Enterprises is a development and design firm and does not manufacture body armor. RANK develops and designs armor according to customer's specifications. We also assist customers in finding armor suppliers.

We design body armor in compliance with NIJ standard 0101.03 Type I to Type IV. A detailed table with descriptions of the various types is available here.

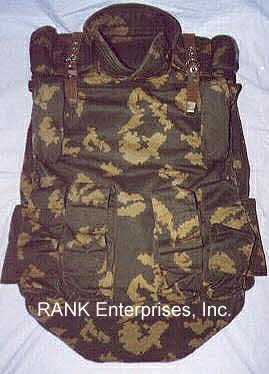

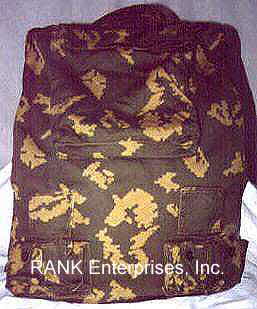

Following are several examples of our military types of body armor, generally complying with NIJ Type III and IV.

Titanium Plate Armor

This NIJ Type IV compliant vest utilizes an arrangement of titanium plates in a "fish scale" configuration. The titanium, though somewhat less ballistically efficient than advanced

ceramics (such as silicon carbide or boron carbide), has the advantage of excellent multi-hit capability. The "scale" design provides some flexibility, and a external layer of fibrous material prevents ricochets. This NIJ Type IV compliant vest utilizes an arrangement of titanium plates in a "fish scale" configuration. The titanium, though somewhat less ballistically efficient than advanced

ceramics (such as silicon carbide or boron carbide), has the advantage of excellent multi-hit capability. The "scale" design provides some flexibility, and a external layer of fibrous material prevents ricochets.

Metal plates in combination with an appropriate design provide the ability to quickly replace individual plates that were damaged in combat. This armor suit is a particularly good

design for military applications requiring good field maintainability and ability to withstand handling by troops

Boron Carbide (B4C) Shield

This NIJ Type IV armor uses a hard ceramic shield to provide resistance against 7.62 FMJ bullets. It has several unusual design features, such as a layer of shock

absorbing material inside the vest that also provides floatation. This makes the vest a very good choice for special forces operations. This vest provides water displacement to assist in swimming and also insures minimal trauma to the wearer with excellent multi-hit capabilities. This NIJ Type IV armor uses a hard ceramic shield to provide resistance against 7.62 FMJ bullets. It has several unusual design features, such as a layer of shock

absorbing material inside the vest that also provides floatation. This makes the vest a very good choice for special forces operations. This vest provides water displacement to assist in swimming and also insures minimal trauma to the wearer with excellent multi-hit capabilities.

The shock absorbing layer is made of fire resistant fibers in a hex cell configuration and is coated with a layer of rubberized

sealer. Due to its shock absorbing properties this layer compensates for the thinner layer of fibrous material used in the ceramic backup plate.

Aluminum Oxide Shield

This vest complies with NIJ Type III requirements and uses alumina (Al2O3) tiles to defeat non Armor Piercing (AP) bullets. This vest complies with NIJ Type III requirements and uses alumina (Al2O3) tiles to defeat non Armor Piercing (AP) bullets.

The design is unusual in the application of the alumina tiles: these are arranged in two layers of unequal thickness with a partial confinement of the tiles. This design provides for a much increased ballistic efficiency, thus making this armor as weight efficient as a conventional Silicon Carbide designs at a much lower cost and better multi-hit capability.

|